How to Properly Tighten the Nozzle+Heat Block+Heat Tube Assembly

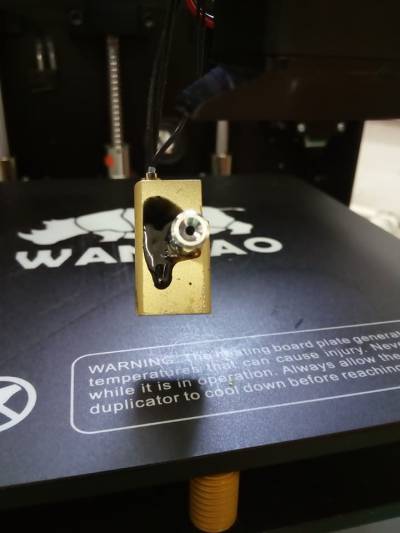

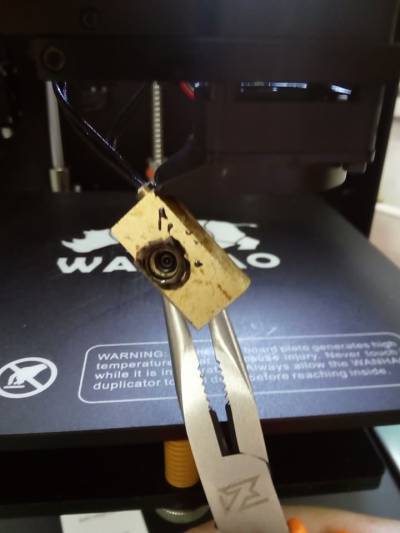

In the above photos, the assembly was not tightened while hot, so there were small gaps between the heat tube, heat block, and nozzle which the molten filament was able to escape through. To avoid this, follow the below procedure:

Proper Procedure

- Assemble the heat tube (silver tube part that sticks up into the extruder body) into the heat block (aluminum or brass middle part with the heater and thermister installed) and the nozzle into the heat block fairly tightly with just your fingers.

- Stick the whole assembly up into the extruder body and tighten the tiny set screw above it to hold it in place.

- Use the printer to heat the nozzle to your highest printing temperature

- Once nozzle is stable at printing temp, use a 19mm spanner to hold the heat block in place, while using a 9mm spanner to tighten the nozzle as best you can

- Retighten the set screw incase the assembly loosened during the process