Printing on Glass

Why print on glass ?

Sometimes the aluminium buildplate will get warped through heat, or some of them are warped from new. The glass will provide a nice flat surface to print on, second the printed object will get that very nice mirrorlike finish on the bottomlayer (if the buildplate is levelled ok)

10,5 cm tall figure with moving joints

There are many solutions to printing on glass, i will name the most simple one(s)

* Boroslicateglass = expensive, it may last longer but in my opinion it is too expensive.

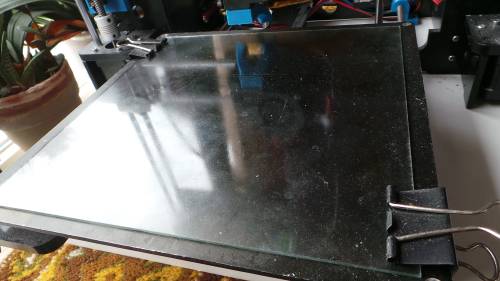

* Pictureframe = the cheapest way to go. I myself use a 2mm sheet 20cm x 20cm attached to the buildplate with 2 clamps. Frame bought for 1 euro, took the glass out, sandpapered the edges to get rid of the sharp bits. 2mm is thick enough to use as long as you treat it carefull enough to not break it and it is light enough to minimize the effect on weight of the moving buildplate

For adhesion i spray it with “a whiff” of cheap hairspray, i found out the more expensive brand was too sticky to use. When hot, the plastic sticks to the glass perfect, when cooling down it releases itself after a few minutes through shrinkage.

If and when the glass gets dirty, just clean it under a running tap with some hot water, the hairspray will dissolve very quick and the bits that do not remove themself you can wipe away with an abrasive sponge (not steelwoll).

Clamps for the glass placed left back and right front are almost never “in the way” of the moving extruderhead and 2 should be enough to hold the glass in place.

![[[]] [[]]](https://3dprint.wiki/_media/printers/parts/beds/20170428_094436.jpg?w=200&tok=20dda9)