This is an old revision of the document!

Change Nozzle

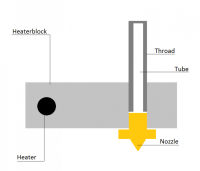

There are several reasons, why you need to change or repace the nozzle, e.g. a clogged nozzle or to change the diameter. Unscrew the old nozzle. If it stucks into the hotbed, heat it up. This way you can easily unscrew the nozzle.

Screw the new nozzle into the heatbed and make sure it touches the throat to prevent it from leaking. If you changed the nozzle Diameter, you need to change your slicer settings.

Leaking filament

A bad assembled hotend is the reason for leaking. To fix this screw the throat so that it touches the nozzle. Make sure that you don't place the throat upside down. Usually at one end of the throat the PTFE Tube comes out slightly, this is the end that has to touch the nozzle. On the other end the tube is not aligned with the throat and has a 40° angle to guide the Filament into the tube, this is the end that goes into the Extruder.