This is an old revision of the document!

Understanding the heat bed

This article documents the tests and analysis I have made to understand my A8 Anet printer heat bed. (at work)

Summary & main conclusions

The A8 Anet heat bed is designed quite at the limit. Small effects may prevent you from achieving temperatures above 100°C. To achieve higher temperatures many measures are needed. The heat-bed can just reach the temperature needed for ABS under ideal conditions.

Here are the main recommendations for those who just want the results:

- Insulate against thermal conduction losses - thick insulation is needed to have a significant effect. Use as much insulation material as you can fit under your heat-bed.

- Insulate against thermal emission losses - a considerable amount of power is emitted as infrared radiation. This can be easily reduced by using aluminium foil as a cover layer on the bottom.

- Increase the voltage at the heat-bed:

- Thin wires create a significant voltage drop between the power supply and the board, and from the board to the heat-bed. Replace the wires by AWG 14 or AWG 16 silicone wires.

- You might increase the voltage of the power supply - but be careful not to overload the power supply.

- Use an enclosure - this increases the temperature by preventing losses via air convection.

If you what to simulate your heat bed here is the simulator:warm_up_2.xlsx

One interesting point is that the current decreases at higher temperatures due to the temperature dependency of the electrical resistance.

For those who what to know the details, here is the full report.

Introduction

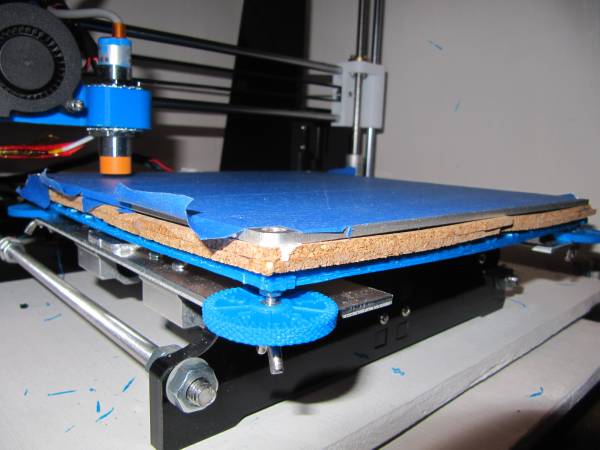

My heatbed could not reach temperatures above 102°C and normally skynetV2 already aborted at 92°C. I thought that if I would just insulate the heatbed bottom I could easily reach higher temperatures. After appling some kork on it I was realy disaponted from the result because it nearly changed anything. So I started analyzig how this can be. Here are my so evereybody can use them.

How I tested

My printer is an Anet A8 without modifications on the board, power supply or wiring (initially).The Firmware was SkynetV2. I tested always inside a (large) plaster enclosure (not fully closed). Unfortunatly I couldn't measure the temperature inside but it was always between 18 and 28°C based on sporadic measurements. The temperatures on the heat bed where read from the display. I noted each minute the value displayed. The setpoint of the heater was set at the beginning to 115 either by Gcode, warm up procedure(aborted by SknetV2 at always around 92°C) or manual control(No abort). The Insulation was two layers of 3mm Kork plates glued together. These where pressed against the heatbed bottom by a blue ABS frame. The heater itself is still glued to the aluminum sheet.

First test results

The fist test has been conducted with heat bed without insulation (there is some timing errors at the beginning of ther red curve). Skynet3DV2 aborted the heating procedure probably because it was not fast enough and a error was triggered at 92°C. I restarted the heating after some minutes.

In order to see the maximum temeprature reachable I had to set the bed temperture via control→ temperatures. This resulting green curve are these tempertures. It topped out at 102°C.

That the initial gradient is always the same is expected because the thermal capacity of the heatbed(appox. 0.426kg * 890J/kgK=379J/K) and the power dissipted by te heater (approx. 105W) is the same. and there are nearkly no heatloses. The gardinet fit to the expected value of 110W / (379J/K) = 17.4K/min.

The curve flattens as the heat loss incearses. Reaching a steady state where the amout of disspated power equals the heatloss to the environment. This equilibrium is explained later in detail. Basically with an better insulation this later part is expected to be steeper and raech a higher final temperature.

My initial thought was that, if I add a little bit of insulation at the heat bed bottom could nearly eliminte half of the heat losses and easily increase the final temperture. Well, lets say just learned something. It was very disapointing to see that the curves where nearly identical and no effect was visible. I had to find out why my expectations where wrong and started investigating it in more detail.

Reproducing the test

I reproduced the test with several configurations. A small (aparent) improvement was achived by taping the sides. But nothing dramatic.

Investigating other effects

A good hint by a facebook group memeber was to check the cables. There is an significant power drop from the voltage supply to the heat bed. Note that the power dissipated at the heat bed is proportinal to the squares of the voltage at the heat bed .

So by replacing the power suplly to heat bed wires with thicker, shorter wires I could increase the power a little bit. But this is not related to the heatbed heatloss or an inisulating effect. I also investigated if the problem was the forced convection due to the extruder fans. I could achieve slight imporvements but nothing spectacular. Dan Rogers posted his results (only 2 points) independently for his heat bed and it shows that mine is not out of family.

.

.

The power supllied to the heatbed

As the curves where very similar I investigated if the controller was ajusting the PWM duty cycle and therefore the curves where a controler effect and not a thermodynamic. The voltage was a flat line on the osziloscope, therefore this theory was discarded.

Than I measured the current and observed that it drops with increasing temperature.

If the resistance is calculated by divinding the voltage through the current this leads to the following resistance

And this gradinet fits nearly to the gradient expected for cupper with an temperature coefficient of appximatly 0.0039 1/K

This is probably also the reason why there are values of 1.2 to 1.6 Ohms mentioned in some forums and sites for this heat bed.

Simulating the heat bed

In order to undertstand the heat bed behavior in more datail I made a heat bed simulator in excel (dispite I don't like to this software for simulations). It fits quite well to the measured data, therefore it seems to be not so bad. But keep in mind that it is a model and not the reality.

The cool thing about simulations is that you can evaluate heat fluxes which are difficult to measure and to make a serios of variations which would require months of testing in a few minutes.

When the steady state is nearly reached the initial 110W of electric power are reduced to 0 by the following contributions (for a heat bed without insulation). It can be seen that a large portion of the heat is irradieted by infrared radiation. This should possible to easily reduced by a factor of 8 to 9 by applying a aluminium foil(emissivity 0.11) beneath the heatbed or insulation.

Analysis with the simulator

It can be seen with these curves that a quite thick insulation is nescessary for a large effect onto the heat curve.

Nearly half of the of the heat is lost by infrared heat radiation. Therefore an aluminum foil at the bottom is more effective than 6mm of kork. To reduce the heatloss even more combine them.

It can be seen with these curves that increasing the voltage on the heatbed increases the speed and max temperature. This can be achived by 3 measures:

- Use thicker wires between HB and board and board and power suplly.(see the optimization chapter below)

- Solder the wires directly onto the heatbed (some soldering practice needed)

- increse the voltage of the power suplly. This might be risky and is only recomended if you have replaced the orignal connectors. The power suplly might exeed its limits, therefore a power suplly with 30A at least is recomended by some users if 14V is used. Thoretically the arduino in the Anet board can go up to 18V but only 12V is recomended for arduinos. So it should be possible but it is your own risk.

Some research in the net

The heatbed for the A8 was increased to 220x220mm from the original Prussa i3 design with 200x200mm. Aparently the power was not not scaled accordingly.

Some recomendation say you need 0.6 W/cm² for a heat bed. This would mean 290W for the A8 heat bed. But it has not even half(110W) of it.

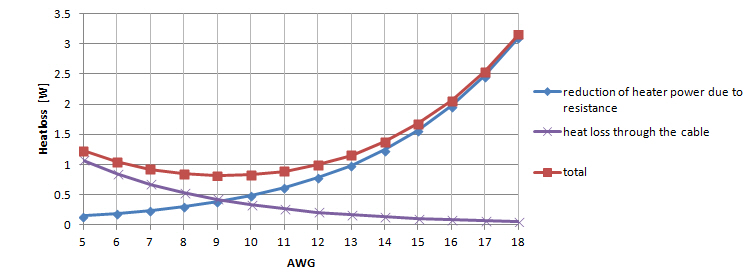

The optimal wire

The original wires from the Anet printer are thin and therefore have an resistance which lead to an power reduction of the heat bed. If you use extremly thick wires you it will be a mechanical issue for the Y-axis stepper and as cables are made of very good thermal conductors it will remove heat from your heatbed by conduction. This rough estimation shows that AWG 9 would be an Optimum from the thermal point but the difference from an AWG 14 is minimal and AWG14 is conciderable more flexible and can be crimped with blue pre insulated crimps. Also the 1 W more for AWG16 would be ok as this as 1W would increase the max heat bed temperature by only 0.5K. I recomend silicone wires with thin strands due to their flexibility.