How to Change a Nozzle

There are several reasons why you might need to change or replace a nozzle, e.g. a clogged nozzle or to change the nozzle diameter.

Unscrew the old nozzle. If it's stuck in the heaterblock, heat it up. This should make it easy to unscrew the nozzle.

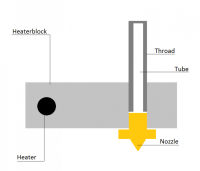

Screw the new nozzle into the heaterblock and make sure it touches the throat to prevent it from leaking. If you changed the nozzle Diameter, remember to change your slicer settings.

MK8 nozzles are compatible with the A8.

Leaking filament

A badly assembled hotend is the reason for leaking.

To fix this, unscrew the nozzle and the throat and clean them. Screw the nozzle back in until there is a 1mm space between the nozzle and the heaterblock. Now screw the throat in until it's firm against the nozzle - make sure that you don't place the throat upside down!

Usually at one end of the throat the PTFE Tube comes out slightly, this is the end that has to touch the nozzle inside the heaterblock. On the other end, the tube is not aligned with the throat and has a 40° countersink to guide the Filament into the tube - this is the end that sticks out of the extruder.

If it still leaks, heat up the hotend and tighten the nozzle against the throat even more.